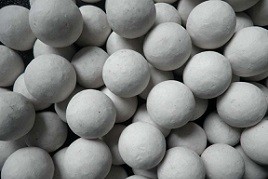

Ceramic Balls

Ceramic balls are spherical objects made from ceramic materials, which are non-metallic, inorganic compounds often composed of metallic and non-metallic elements. Ceramic balls find various applications due to their specific properties. Here's an overview:

Composition and Types:

- Ceramic balls are made from a range of ceramic materials, including alumina (aluminum oxide), zirconia, silicon nitride, and others.

- Different ceramic materials offer varying degrees of hardness, wear resistance, thermal stability, and other properties, making them suitable for different applications.

Applications:

- Ball Bearings: Ceramic balls are used in high-performance ball bearings due to their high hardness and low friction, contributing to reduced wear and increased lifespan.

- Valve and Pump Components: They can be used in valve and pump components to provide excellent wear and corrosion resistance, especially in abrasive or chemically aggressive environments.

- Grinding Media: Ceramic balls are used as grinding media in mills for processes like milling, dispersion, and fine grinding of materials. They're often chosen for their high grinding efficiency and reduced contamination risk.

- Precision Applications: In precision machinery and equipment, ceramic balls are used for their dimensional stability, smooth surface finish, and resistance to wear.

- Chemical Applications: Ceramic balls are used as catalyst support, adsorbents, and fillers in chemical processes and applications.

- Insulating Applications: In electrical and electronic applications, ceramic balls can be used as insulators due to their non-conductive properties.

Advantages:

- High hardness and wear resistance, leading to longer service life in applications prone to abrasion and friction.

- Excellent corrosion resistance, making them suitable for harsh environments.

- Low thermal expansion and good thermal stability, allowing them to maintain their shape and properties at high temperatures.

- Non-magnetic and non-conductive properties in some ceramics.

Limitations:

- Brittle nature: Ceramic materials are generally more brittle than metals, making them susceptible to cracking or breaking under high impact loads.

- High cost: Depending on the material and manufacturing process, ceramic balls can be more expensive than steel balls.

- Careful handling: Due to their brittleness, ceramic balls may require careful handling and proper load considerations in certain applications.

Ceramic balls offer a combination of properties that can be advantageous in specific applications where their unique characteristics are needed, such as high-temperature environments, chemically aggressive surroundings, or precision machinery. The choice of ceramic material and ball size should be based on the specific requirements of the intended application.