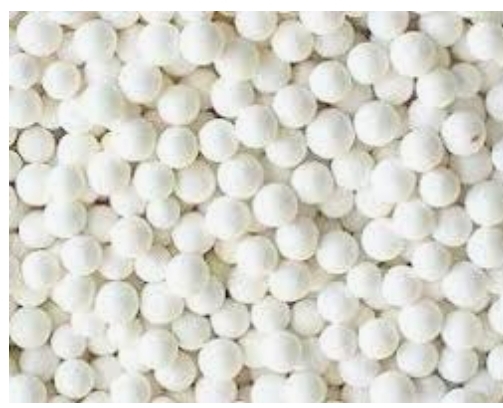

Activated Alumina

Activated alumina is a porous material with a high surface area, commonly used as an adsorbent in various industrial applications. Here's an overview:

Composition and Structure:

- Activated alumina is primarily composed of aluminum oxide (Al2O3), often in the form of spherical beads or pellets.

- It has a highly porous structure with a large surface area, which provides ample sites for adsorption and chemical reactions.

Adsorption Properties:

- Due to its porosity and surface area, activated alumina has a strong affinity for adsorbing water vapor and other polar molecules.

- It can effectively remove moisture from air or gases, making it useful in drying and purification processes.

- Depending on the application, activated alumina can also adsorb other impurities like fluoride, arsenic, and other trace contaminants.

Applications:

- Desiccant: Activated alumina is widely used as a desiccant for drying air and gases. It's particularly effective for removing water vapor from compressed air systems.

- Fluoride Removal: In water treatment applications, activated alumina can be used to reduce fluoride levels in drinking water.

- Catalyst Support: It serves as a catalyst support or carrier in various catalytic processes, such as in the petroleum and petrochemical industries.

- Drying of Solvents: Activated alumina is used to remove moisture from solvents in laboratory and industrial settings.

- Gas Purification: It can be used to purify gases by adsorbing impurities and contaminants.

- Pressure Swing Adsorption (PSA): In some cases, activated alumina is used in PSA systems for gas separation, similar to carbon molecular sieve.

Regeneration:

- As activated alumina adsorbs moisture or other substances, it becomes saturated and requires regeneration to restore its adsorption capacity.

- Regeneration is often done by applying heat, either through heating the adsorbent bed or by passing a heated gas through it. This process drives off the adsorbed substances, making the material ready for reuse.

Advantages:

- High adsorption capacity due to its large surface area and porous structure.

- Versatile material with applications in various industries.

- Regenerable, extending its useful life.

Limitations:

- Limited adsorption of non-polar substances.

- May require careful handling due to its delicate nature.

Activated alumina's ability to adsorb moisture and certain impurities makes it valuable in industries where drying, purification, and separation processes are crucial. It's important to consider its specific properties and characteristics when selecting it for a particular application.